For over 100 years, the dynamic loudspeaker has undergone many changes in shape, style, impedance and materials, but one constant has remained: a speaker’s diaphragm—the main part that moves air—needs to be directly coupled to open air for any appreciable sound to be created in volume.

This requirement of a speaker opening (for efficient use) can introduce undesirable aspects into products and devices where speakers are integrated. Be it the changed aesthetics of an otherwise slick, sleek design or the introduction of the product to hostile environment variables such as rain, dust, vandalism, or sunlight exposure.

With the introduction of PUI Audio’s new line of Audio eXciters, many of the challenges that design engineers now face when integrating audio can be overcome without sacrificing output.

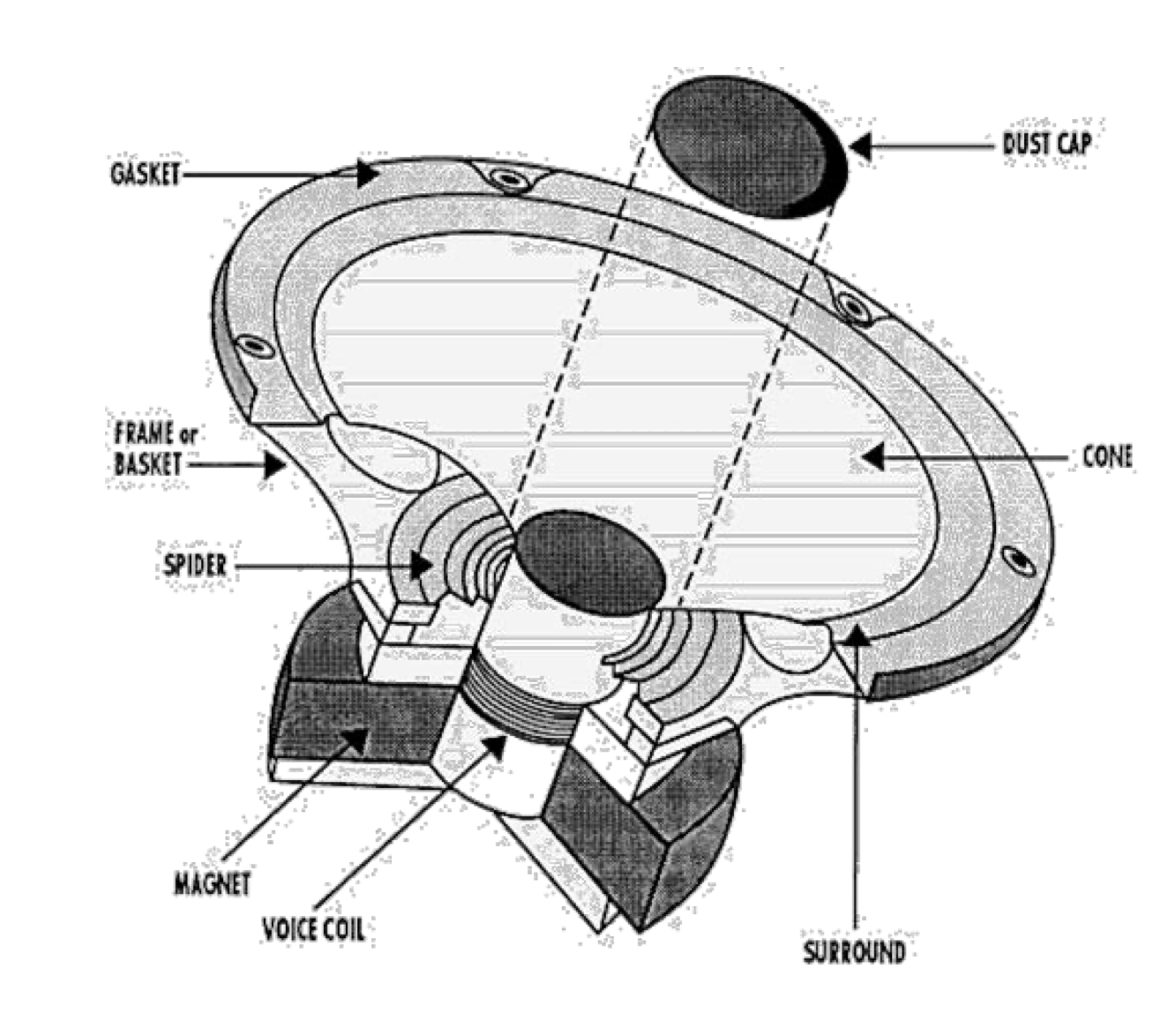

Audio exciters are built on the same principal as speakers, where there is still a permanent magnet and a moving voice coil to generate sound, directly proportional to an audio signal. However, that is where the similarities end. A speaker relies on the diaphragm (attached to the voice coil by a former) to modulate air and make sound.

Exciters, instead, rely upon the voice coil being coupled directly to the inside surface of an object, transforming that object’s outer surface into an invisible, protected speaker by imparting vibration from the exciter’s moving mass into the surface.

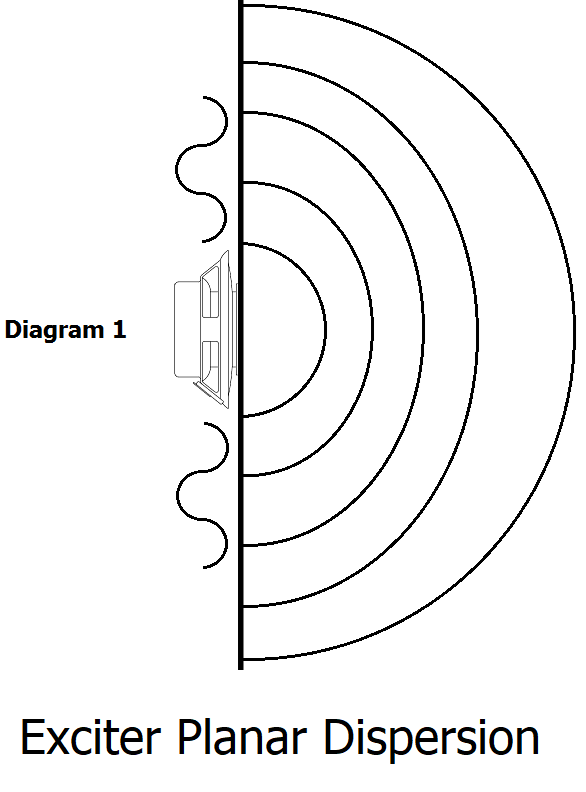

The vibration of the surface modulates air in such a way that sound is created in planar-wave fashion. What this means is that (similar to planar and ribbon-type speakers) on and off-axis frequency response is nearly linear without even drop-off.

Listeners can be positioned up to 90° off-axis of the excited surface and experience the same sound quality as a listener positioned directly in front of the excited surface (Diagram 1).

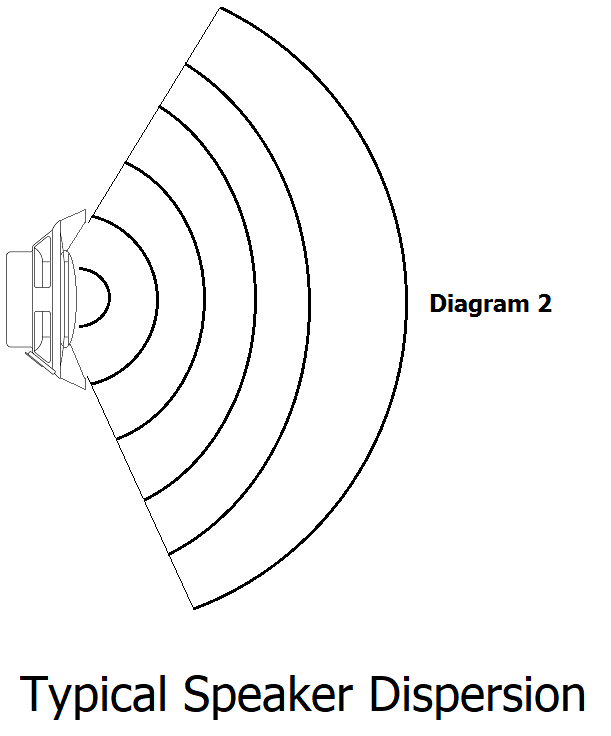

Typical speaker dispersion (Diagram 2) is such that frequencies above 5 kHz tend to become attenuated, starting at angles as little as 15° off-axis.

Most exciters are also easier to implement than similar-size speakers as they do not need to be chambered or mounted into an “optimized” enclosure for exceptional low frequency reproduction.

Many product designers mount speakers on bosses or stand-offs that prevent an annular seal from being created around the perimeter of the speaker’s frame or diaphragm. This introduces cancelation as the front of the speaker’s diaphragm is free to interact with the rear of the speaker’s diaphragm, creating loss of low frequency reproduction.

Exciters not only use the interior of a device as an enclosure, the coupling with a surface creates an annular seal, preventing cancelation.

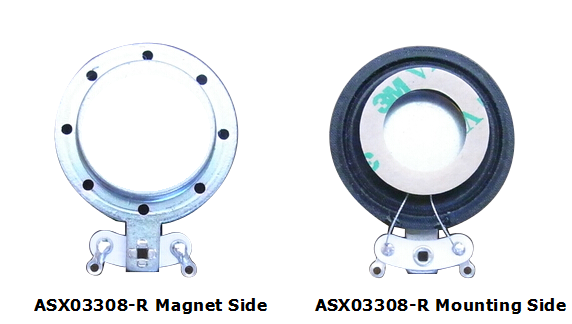

Most PUI Audio eXciters employ 3M™ VHB™ (very high bond) double-sided tape on their mounting rings for quick, safe and secure surface coupling. If your product is subject to shock, extreme heat, or extreme cold, it is recommended to use a mounting feature/bracket to take the mass of the exciter off of the VHB. Please contact PUI Audio for more information.

Material type and thickness alter frequency response and affect the sound pressure level.

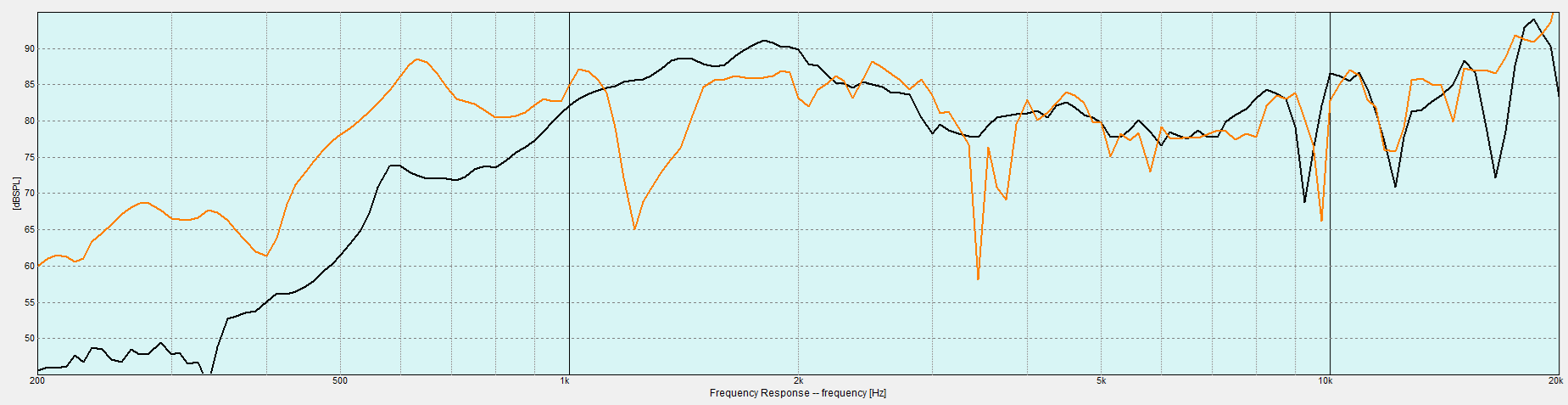

Below are frequency response measurements taken from the ASX07008-WP-R when mounted in the same location on 2 mm (black) and 4 mm (orange), 190 mm diameter plates made of the same PLA material. The thinner material has more overall output from 1 kHz to 2 kHz, while the thicker material exhibits more output below 1 kHz.

The ideal material to use with an exciter would be lightweight, dense, and able to bend. The density of the material affects high frequency performance above 4 kHz (treble). Typically, a higher density material will yield more high frequency output.

A material’s ability to bend affects low frequencies from 10 Hz to 250 Hz (bass) and mid-level frequencies from 250 Hz to 4 kHz (midrange). Materials that are more flexible will typically yield higher output in these ranges.

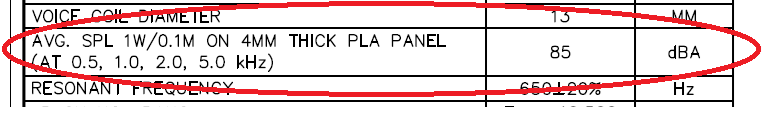

Use the average sound pressure level (AVG. SPL) rating on the specifications to select by sensitivity. Multiple exciters may be needed to be used on heavier materials.

Some materials, such as metal panels, may impart their own sound to the output of the exciter, which may produce unintended audio output effects. Contact PUI Audio for assistance at reducing these effects.

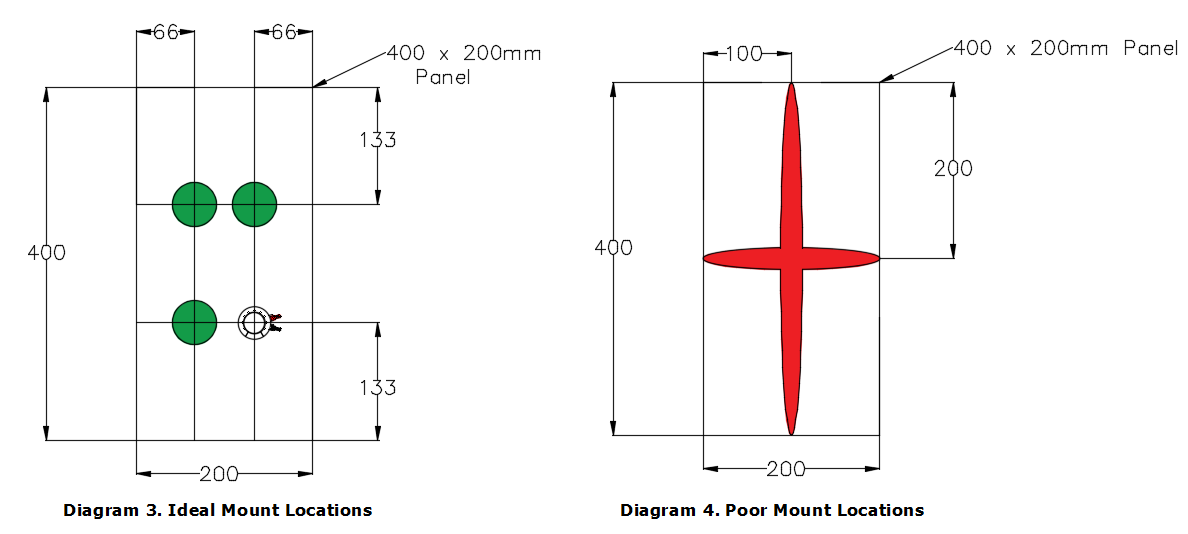

Before mounting an exciter, measure the overall surface to each nearest edge. Divide each dimension into thirds. The ideal mounting location is where 1/3 of one dimension intersects with 1/3 of another dimension (illustrated in Diagram 3). This reduces standing waves that can dominate the output of the exciter. Always try to avoid placing an exciter directly in the middle of dimensions (illustrated in Diagram 4).

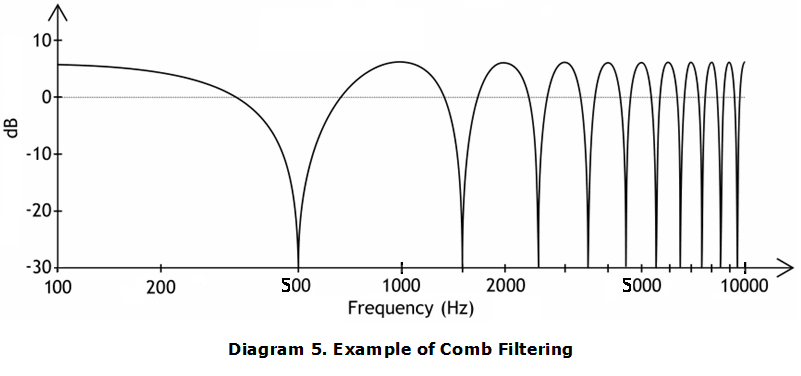

If multiple exciters are needed for higher output, try to avoid spacing them evenly about a surface (or panel). This introduces comb filtering on the surface, where one exciter starts to cancel out the midrange to high frequency output of another exciter.

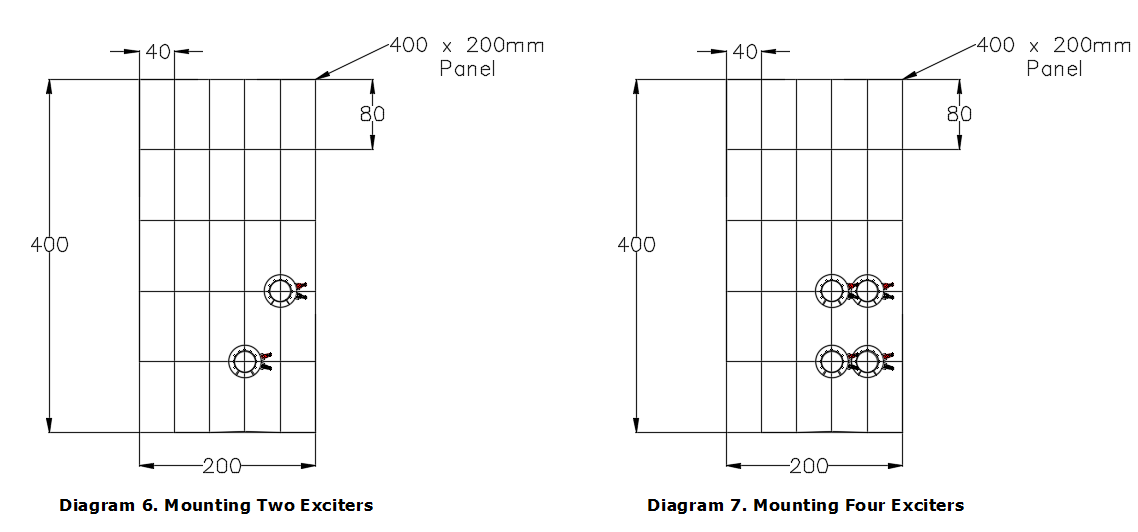

When placing multiples, measure the length and width to the nearest edge, and divide each dimension into fifths. Mount the exciters on the nearest one-fifth intersections of the two dimensions.

Prior to mounting an exciter using the provided 3M™ VHB™ double-sided tape, clean the mounting surface as thoroughly as possible using alcohol to remove any oil, dirt, or debris which could prevent a positive contact area.

In the event that you are using a mechanical mount to hold the exciter in-place against a surface, PUI Audio recommends bonding the voice coil of the exciter to the surface with hot glue, epoxy, and double-sided tape. This prevents unwanted buzzing.

Audio output can also be focused or made to be contained on a panel with the use of a material such as rubber, or asphalt-based damping sheets. These can also be used between the exciter and the surface that the exciter attaches to for attenuating high frequencies.

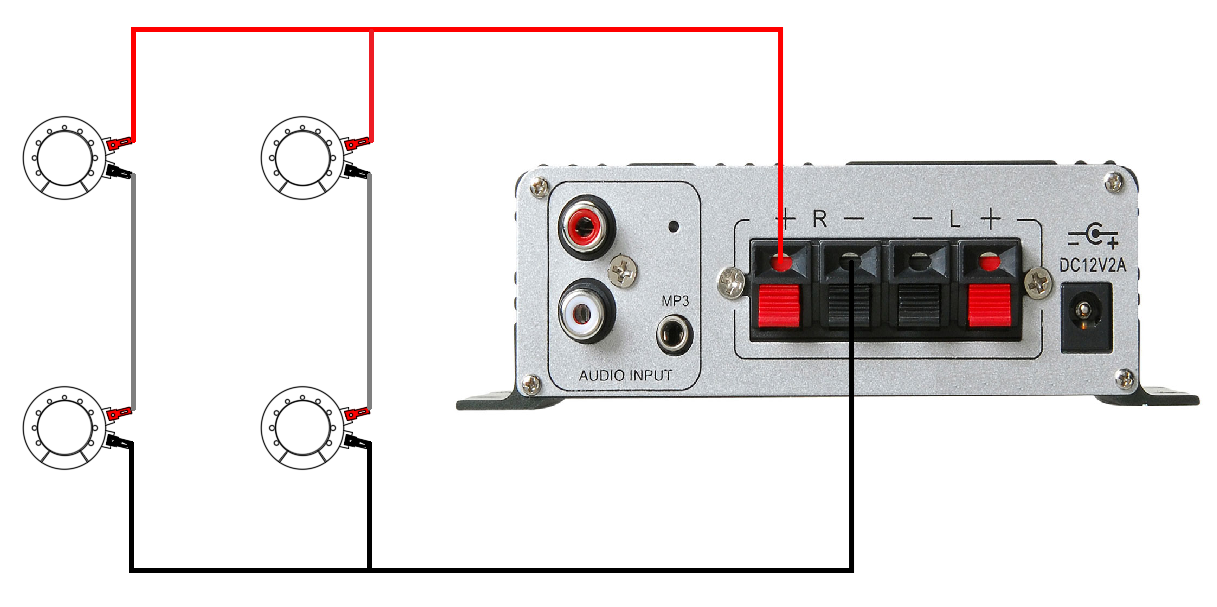

Wiring and powering exciters is exactly the same as that with speakers. PUI Audio’s eXciters are offered in 4 and 8 ohm impedances. If using multiple exciters, you can wire them in series, parallel, or series-parallel (shown below).

A series-parallel wiring scheme for multiple exciters will maintain the same impedance as one exciter, provided the number of exciters used is a perfect square (e.g. 4, 16, 25, and so on).

For applications or products that are to be subjected to external force, shock, or vibration, PUI Audio recommends solid mechanical reinforcement to ensure rigid coupling beyond that provided by the 3M™ VHB™ F-9473PC double-sided tape.