Electromechanical Transducers

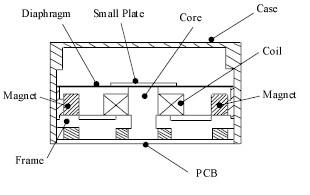

Electromechanical transducers make sound in much the same way as speakers. Inside the housing, a diaphragm is magnetically pulled towards the core due to interaction between a magnet and a coil. When positive-biased square-wave signal is applied, the current flowing through the coil produces a fluctuating magnetic field which causes the diaphragm to vibrate, thus, producing a sound.

The frequency of the sound produced is the same as the frequency of the input signal. Electromechanical audio indicators (AI devices) have built-in oscillators and wave shaping networks to produce siren, pulsating, or continuous tone sound output when a DC voltage is applied.

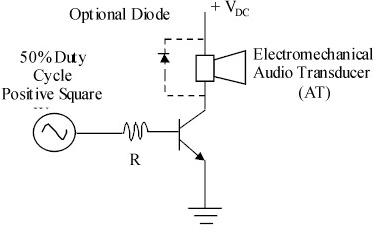

For the highest SPL, it is recommended to drive electromechanical transducers at, or near, their listed resonant frequeuncy with a positive-biased square-wave (V0-p) with a 50% duty cycle. It is possible to control the volume of the device by varying the duty cycle away from 50%, though a slight change in tone will occur.

Drive Circuits For Electromagnetic Transducers

As mentioned above, electromechanical audio indicators only require a DC voltage supply to turn the device on. Audio transducers, on the other hand, require a tone generating drive circuit to operate. Below is an example.

Single-Ended Drive Circuit with Flyback Diode for Protection